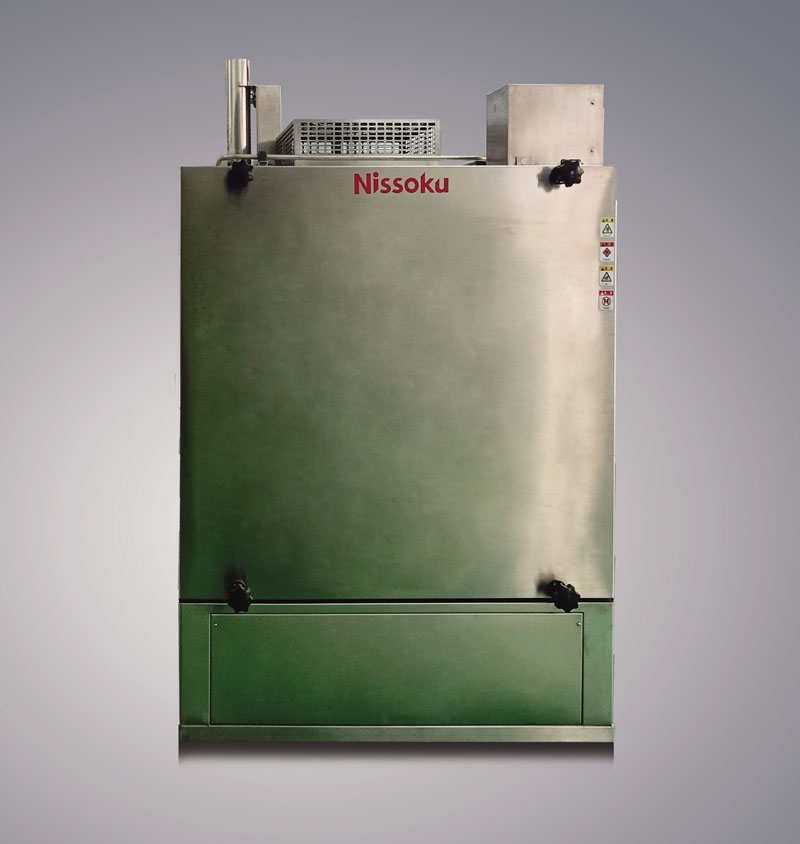

In the production process of automotive electronic devices, potential defective products are inevitably produced due to differences in raw materials, fluctuations in manufacturing processes, and other factors. Environmental reliability testing can simulate various extreme and typical usage environments, such as high temperature, low temperature, humidity, dust, etc. For example, in the testing of automotive engine control units (ECUs), temperature cycling tests (from -40 ° C to 125 ° C) can detect whether electronic components will experience issues such as solder joint cracking and chip performance degradation during temperature changes. Products that cannot withstand these environmental tests will be exposed to defects in advance, thus being screened out and avoiding entering the market.

- IS016750

- AEC-Q-100

- AEC-Q-101

- AEC-Q-102

- I EC60068-2

- MIL-STD-810

- JIS-D0204

- JIS-D5814